Significance of SHIONOGI’s Challenge in the “Resource Recycle Project”

Recycling from Upstream to Downstream Within the Project: A Responsible and Valuable Initiative

Could you tell us about the horizontal recycling project for label backing sheets?

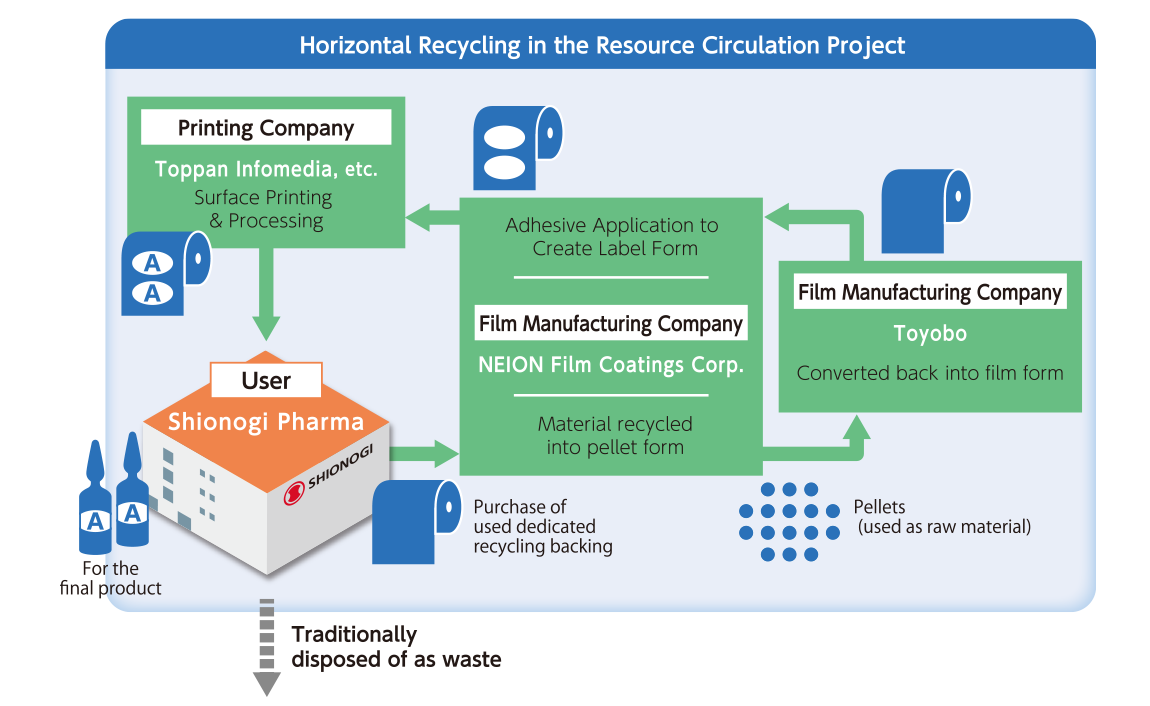

In this project, we are recycling the label backing sheets (i.e., release paper, label liner). Although labels are critical for displaying information in the pharmaceutical industry, most of their backing sheets are not recycled as resources but discarded or incinerated. Essentially, an equivalent number of backing sheets to the labels produced is generated and disposed of. It is estimated that, in total, 1.39 billion m2 label backing sheets are annually discarded during manufacturing across Japan; this is approximately the equivalent of 30,000 Tokyo Domes.

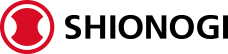

The backing sheets have not been recycled in the past because of their construction. The sheet surfaces, which are typically made from paper, are coated with plastic or silicone to facilitate easy removal of labels. This coating complicates recycling because of its contaminants, which are difficult to separate in the recycling process.

What is horizontal recycling?

Could you explain the structure of the Resource Recycle Project?

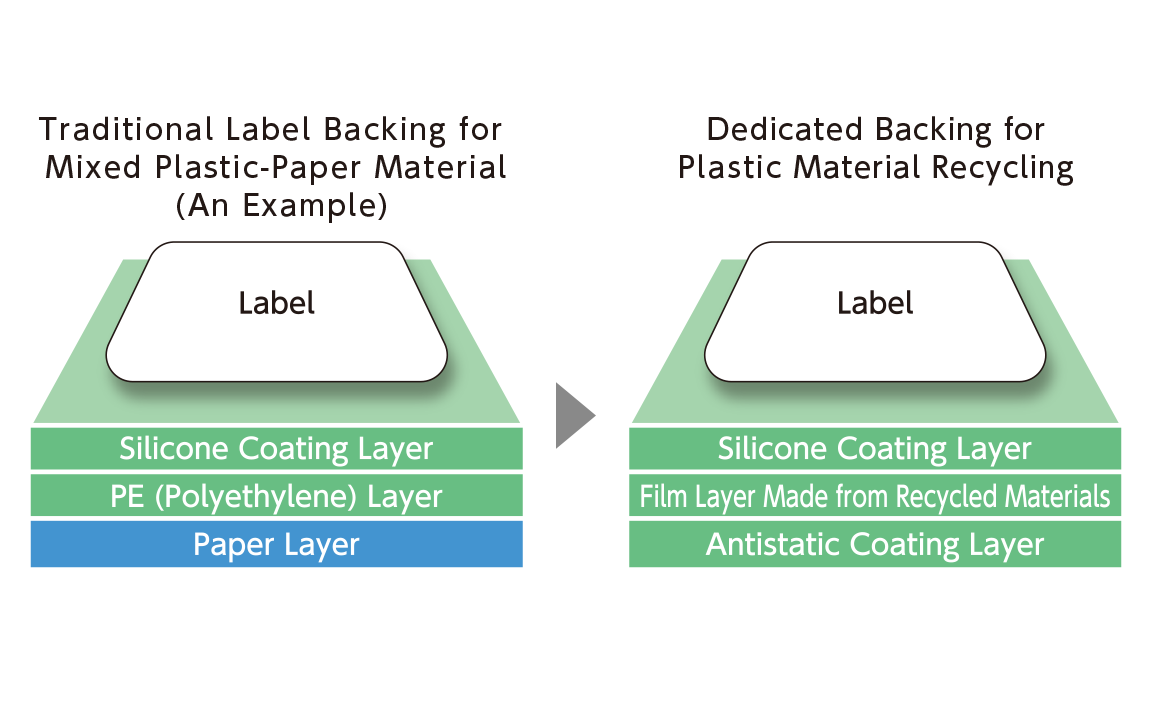

The Resource Recycle Project has established functions at the “upstream,” where products are created, and the “downstream,” where waste is collected and recycled. Upstream begins with the production of the film that will become the “recycling-specific backing sheet.” This film is coated with an adhesive to create the base material for labels, which are then printed and cut into shapes, eventually reaching label users like Shionogi Pharma.

The products with applied labels reaching people is followed by downstream. Once sufficient quantities are accumulated, these are transported to recycling facilities across the nation using the Yamato Group’s logistics network, where material recycling is carried out; in this process, contaminants are removed, and the backing sheets are finely shredded into flakes, which are then melted at high temperatures and form pellets. These pellets are used as raw materials to produce new films, completing a cycle repeated throughout the project scheme.

When I first heard about this project, I was deeply impressed by its commitment to responsibly managing and advancing the initiative at the upstream and downstream ends. Viewing used products as new resources and creating a sustainable cycle is highly valuable in promoting sustainability.

Cooperation and Words from Other Teams Drive Progress

How you got involved in the horizontal recycling project for label backing sheets?

In June 2021, while attending the “1st Kansai Sustainable Material Expo” held in Osaka, I learned about this initiative from NEION Film Coatings Corp., which is exhibiting its environmental business projects. It was an eye-opening moment. Until then, my department was responsible for designing and developing pharmaceutical containers and packaging materials; however, we did not focus on the waste generated at our factories—it was a completely new perspective. Afterward, Mr. Motoike from NEION Film Coatings Corp. explained the project structure in detail, and we hit it off with the idea of collaborating across the supply chain to codevelop solutions. I have been involved since the initiation of building the collaboration framework.

Regarding the partnership, there were moments when the negotiations for the joint development agreement reached a deadlock due to differing opinions among the companies. However, everyone was committed to doing something good for the environment; this ultimately helped us to overcome internal and external barriers and start the pilot project in April 2022.

Were you personally interested in the project?

What were the biggest challenges of the project, and how were they overcome?

The pilot project started in April 2022, and it took a year to reach commercial application. This was because the time-consuming optimization of production equipment required switching from paper to plastic “recycling-specific backing sheets.” The change in material affected film properties—such as stretch and slipperiness, as well as light transmittance—necessitating adjustments to sensors on the label applicators and a complete review of all production settings.

Another challenge was the use of actual production lines for the experiments. Naturally, stable product supply was a priority, and we sometimes could not conduct experiments for approximately 2 months because of production schedules.

During the pilot project, members of the Settsu Factory Manufacturing Second Team cooperated with the tests, working them in between regular production activities. Trying something new always involves risks, and it is common for the sentiment of “maybe it is better not to change” to emerge. However, during this project, there was active encouragement from Mr. Nishimura, and other team members, who were very supportive of the changes, urged us to “go for it!” The entire team’s commitment to tackling various challenges with a positive attitude was a driving force that enabled us to successfully complete these pilot tests.

Can you share any memorable episodes from the project?

Last year, we received an award within the SHIONOGI Group , and a comment from Environmental, Health, and Safety team member who handles waste remains vivid in my memory: “It is like a dream that what we used to pay to dispose of is now collected as valuable material through this project.”

Although only a small amount of waste is reduced by this project, transforming waste into valuable material is remarkable for Shionogi Pharma.

Driving Resource Circulation Across All Industries as a Leading Company

How does applying a circular horizontal recycling scheme to labels for ampoule injections contribute?

CO₂ emission reduction is assessed using Life Cycle Assessment ※. For “recycling-specific backing sheets,” the use of recycled materials in production, and specifically the avoidance of new petroleum use, contributes to reducing CO₂ emissions.

※ Life Cycle Assessment (LCA) quantitatively evaluates the resources used, environmental load, and their impacts on the planet and ecosystems throughout the lifecycle of a product or service—from raw material procurement to manufacturing, distribution, use, and disposal/recycling, often referred to as “from cradle to grave.” The calculations for this project were performed using “LCA Plus,” a decarbonization platform operated by Mitsui & Co., Ltd.

What is the significance of Shionogi Pharma’s involvement in the Resource Recycle Project?

The pharmaceutical industry has traditionally used complex materials that combine difficult-to-recycle components to maintain drug quality. These materials are often specified in regulatory filings, which has hindered progress in this area. Therefore, Shionogi Pharma’s early participation in the project is of substantial importance.

Considering the ubiquity of labels across various products, labels are used in every industry. It is challenging for just one company like Shionogi Pharma to significantly reduce waste and CO₂ emissions alone. Therefore, it is crucial to expand the recycling efforts of the Resource Recycle Project across all industries to collectively reduce these impacts. If all companies using labels join this ecosystem, we can potentially eliminate the disposal of approximately 1.4 billion m2 of backing sheets annually, making this an initiative with significant ripple effects.

The Ultimate Vision: A World Where Recycling Label Backing Sheets is the Norm

Do you plan to expand the “Resource Recycle Project” scheme to other label applications?

We have decided to extend the project and include shipping box labels, starting from the fiscal year 2024.

In addition, we are considering to expand it to process management labels. These labels are used to manage inventories, such as raw materials and supplies in warehouses, during manufacturing and are printed and used within the factory. Even in these nonproduct applications, labels are widely used, resulting in the backing sheets disposal.

Could you share the long-term goals or visions you intend to achieve?

The ultimate vision of this project is to create a society where recycling label backing sheets is the norm. As part of the SHIONOGI Group, we were recognized as an Eco-First Company in 2023, partially because of our efforts with the “Resource Recycle Project”. Each small step contributes to the group’s proactive approach to environmental considerations, which will possibly spread throughout the pharmaceutical industry and to the broader manufacturing sector.

Various industries are interested and participating in this project, thereby resulting in its expansion. Moreover, the material recycling process started operation in April 2024, marking the start of full-scale resource circulation.

Challenges such as waste and CO2 emissions result from cumulative daily activities. The actions we take today impact the global environment for decades to come. We remain committed to pursuing a sustainable society. (A total of 28 companies and organizations are participating as of April 2024.)

Note: The information in this article is based on the status while reporting.